Ultra-High-Purity Analytical Reagents

TAMAPURE-AA Series

The "TAMAPURE-AA" series is an ultra-high-purity analytical reagent developed with the goal of achieving a “World of ZERO impurities”. The TAMAPURE-AA series is used across a wide range of scientific and technological fields such as electronics, environmental science, biochemistry, and medicine.

TAMAPURE-AA Series Features

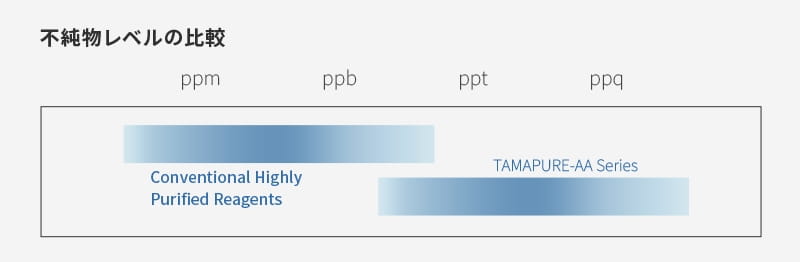

The greatest feature of the TAMAPURE-AA series is its world-class purity, with metal impurity levels below ppt (pg/mL). Another major feature of the TAMAPURE-AA series is its exceptional consistency in quality. Through our proprietary manufacturing and packaging technologies with rigorous quality control, we have significantly enhanced the uniformity of quality between production lots and between individual containers.

Applications

The TAMAPURE-AA series is mainly used as blank and pretreatment reagents in ultra-trace analysis. By using the TAMAPURE-AA series, sample contamination is prevented during pretreatment, reducing blank values and greatly improving analytical sensitivity and accuracy.

Example applications:

- Quantitative analysis of ultra-trace metal impurities in high-purity semiconductor chemicals

- Quantitative analysis of ultra-trace metal elements on silicon wafer surfaces

- Quantitative analysis of ultra-trace metal impurities in diluted sample

- Quantitative analysis of ultra-trace metal impurities in water quality samples

TAMAPURE-AA Lineup

TAMAPURE-AA-10

- Metal impurity levels are kept below 10 ppt.

- TAMAPURE-AA-10 is a further purified reagent compared to TAMAPURE-AA-100.

- Please open it and use it in a clean area of Class 4 or higher.

| Item | Concentration | Packaging |

|---|---|---|

| Hydrofluoric Acid (HF) | 38% | 500g |

| Hydrochloric Acid HCl | 20% | 500g |

| Nitric Acid (HNO3) | 68% | 500g |

| Nitric Acid (HNO3, for overseas) | 55% | 500g |

| Hydrogen Peroxide (H2O2) | 35% | 500g |

TAMAPURE-AA-100

- Metal impurity levels are kept below 100 ppt.

- Please open and use it in a clean area of Class 5 or higher.

| Item | Concentration | Packaging |

|---|---|---|

| Hydrofluoric Acid (HF) | 38% | 500g |

| Hydrochloric Acid (HCl) | 20% | 500g |

| 〃 | 30% | 500g |

| Nitric Acid (HNO3) | 68% | 500g |

| Nitric Acid (HNO3, for overseas) | 55% | 500g |

| Sulfuric Acid (H2SO4) | 98% | 250g |

| Hydrogen Peroxide (H2O2) | 35% | 500g |

TAMAPURE-AA Ultrapure Water

In trace analysis, ultrapure water is used for cleaning devices and containers as well as for sample dilution.

Using TAMAPURE-AA ultrapure water that metal impurities below ppt levels, reduces blank values and yields more reliable analytical results.

- Metal impurity levels are kept below 10 ppt.

- Please open it and use it in a clean area of Class 4 or higher.

- Packaging: 500 g

TAMAPURE-AA TMAH

TMAH, short for Tetramethyl Ammonium Hydroxide (chemical formula (CH3)4NOH), is a strongly alkaline aqueous solution. It is very effective for the quantitative analysis of volatile elements in acid pretreated samples. Compared with commonly used for alkali fusion reagents such as NaOH and KOH, TMAH has the advantage of exhibiting minimal matrix effects.

- Metal impurity levels are kept below 1000 ppt.

- Please open and use it in clean areas such as cleanrooms.

- Packaging: 500 g

Wafer Surface Analysis Scan Solution

TAMAPURE-AA SSX

The TAMAPURE-AA SSX is a scanning solution developed for wafer surface analysis (pre-treatment by the VPD method → dissolution by the DADD method → analysis by GF-AAS, ICP-MS, TXRF). It was developed to meet demands for improved reliability in ultra-trace metal analysis on wafer surfaces and to increase efficiency of cleanroom operations.

・SSX is an aqueous mixture of 2% hydrofluoric acid and 2% hydrogen peroxide.

・Metal impurity levels are kept below 10 ppt.

For detailed specifications, please refer to the following PDF file:

TAMAPURE-AA SSX

Impurity Analysis Techniques

Our Analytical Technology Features

The TAMAPURE-AA series are subject to strict quality control with the latest high-performance, high-sensitivity analytical instruments, excellent analytical techniques, and skilled staff. Pretreatment is conducted in a clean area guaranteeing Class 4 cleanliness within a Class 6 cleanroom, and impurity measurements are performed by ICP-MS. Analytical data are provided with each bottle.

Our company pursues technological development under the major theme of "even higher purity, even higher quality reagents." We possess world-leading technologies in the field of ultra-trace analysis, including the establishment of sample pretreatment techniques that maximize the performance of analytical instruments.